Blow Molding

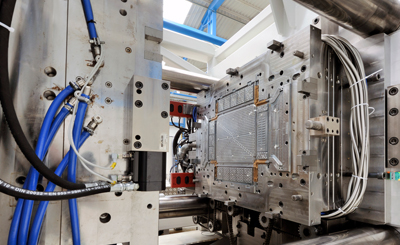

Our Battenfeld and Bekum extrusion blow molding equipment allows us to manufacture products using polyolefin thermoplastics. We utilize shuttle machines which run two molds concurrently, providing twice the normal rate of production. All machine functions are microprocessor controlled assuring one of the highest degrees of control available. The combination of high speed and consistent production allows us to fulfill our customers' needs on time and at the right price.

Specific capabilities for the Plastics Division include:

- Blow molding containers up to one gallon F-type

- Custom product design

- Material selection

- Mold maintenance

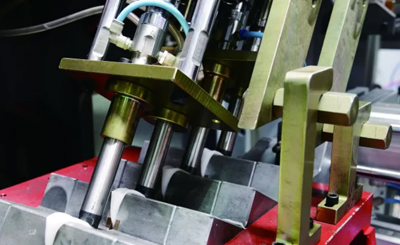

- Automated mechanical assembly

High-Density Polyethylene (HDPE)

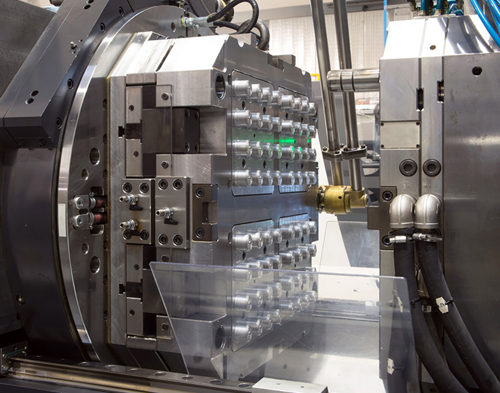

HDPE injection molding is a manufacturing method that employs High-Density Polyethylene (HDPE) as the primary material to produce a diverse array of plastic components and products. The process consists of melting HDPE resin, injecting it into a mold cavity, cooling, ejection, and final finishing steps. HDPE's favorable attributes, including its strength, chemical resistance, and cost-effectiveness, render it well-suited for a range of applications across industries such as packaging, automotive, consumer goods, and construction. This process offers an efficient and economical means of manufacturing plastic parts with various shapes and sizes, establishing it as a widely adopted technique in the manufacturing sector.

Polypropylene (PP)

Polypropylene injection molding is a manufacturing technique that employs polypropylene (PP) as the primary material for crafting plastic parts and products. PP is acclaimed for its exceptional qualities, which encompass high resistance to chemicals, lightweight properties, and cost-effectiveness, rendering it a prevalent choice in numerous industries. The process encompasses melting PP resin, injecting it into a mold cavity, facilitating cooling, and potentially undergoing subsequent finishing steps. Renowned for its versatility and cost-efficiency, polypropylene injection molding is a favored method for the streamlined production of plastic components in a wide array of shapes and sizes, making it particularly popular in sectors like packaging, automotive, consumer goods, and medical devices.

PCR (Post-Consumer Recycled)

PCR (Post-Consumer Recycled) material refers to plastic materials that are recycled from consumer products that have reached the end of their useful life and have been discarded or recycled by consumers. These materials are collected from items such as used plastic bottles, packaging, and various consumer goods after they have been used, discarded, and then recovered through recycling processes.

Post-consumer recycled materials are a crucial component of sustainable and environmentally responsible plastic production. They help reduce the demand for virgin plastic resins, conserve resources, and minimize the environmental impact associated with plastic manufacturing. We use PCR materials to create new plastic products, contributing to the circular economy and reducing the overall environmental footprint of plastic production. Recycling programs and initiatives encourage the collection and processing of post-consumer plastics to reintegrate them into the manufacturing supply chain, reducing waste and conserving resources.

Other Blow Molding

Custom Colors Available!

Colors in plastic injection molding are achieved by adding pigments or colorants to the plastic resin before it's melted and injected into the mold. Several methods are used, including masterbatch, pre-blended color pellets, dry color blending, and liquid colorants, each with specific applications. These colorants are mixed with the polymer material in the molding machine's barrel to achieve uniform color distribution. The method chosen depends on factors like the desired color, production scale, and precision requirements to ensure consistent and durable coloration in the final plastic product. Contact us today to learn how we can create the perfect color match for your project!

©2023 MarCon, Inc.® | ALL RIGHTS RESERVED | Industrial Website Catalog by WYSIWYG Marketing